Product Knowledge

- Applications of HDPE Butt Fusion Machines in Pipeline EngineeringJan 9,2026HDPE butt fusion machines are essential equipment in medium- and large-diameter pipeline engineering. By joining pipes through controlled heating and pressure, butt fusion creates joints that become part of the pipe itself. This process is widely used in water, gas, irrigation, and industrial pipelines, particularly in long-distance and buried installations where long-term reliability is critical.

- FX Series Butt Fusion Machines: Practical Standard AccessoriesDec 30,2025The FX series butt fusion machines include practical standard accessories designed for real job-site conditions. Beyond core components, these accessories improve pipe adaptability, system stability, operational safety, and on-site convenience. Each standard configuration is selected based on repeated use in real construction environments, supporting efficient and reliable butt fusion welding operations.

- Why the Frame Rings of FX800 and Larger Butt Fusion Machines Are Finished in BlackDec 28,2025FX800 and larger butt fusion machines feature black-finished frame rings instead of standard blue. This choice is based on material composition and high-temperature forging results, which can create surface imperfections. A black finish helps reduce the visual impact of these imperfections, providing a more consistent and stable overall appearance suitable for large-scale welding equipment.

- Why Are FusingX Facer Tools More Reliable?|A Closer Look at the Gear-Driven StructureDec 13,2025A gear-driven facer with reinforced plate, stable torque output, and long service life—this article explains why FusingX’s facer delivers more consistent and reliable cutting performance than chain-driven designs.

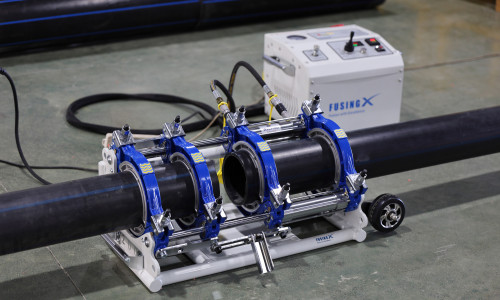

- What Makes Up a Complete Butt Fusion Welding Machine?|FX630 ExampleDec 10,2025A complete butt fusion welding machine includes a main frame, facer, heater, and hydraulic unit, with an optional crane lifter for large-diameter work. This article explains each component using the FX630 setup as an example.

- Understanding the Frame Design of FX250 and FX315 in the FusingX FX SeriesDec 3,2025The FX250 and FX315 use a round-edge steel tube frame, while larger FX models adopt a thickened steel plate structure. Each design is chosen to match the mechanical demands of its pipe size range.

- FX Series Fusion Welders: Engineered for Excellence, Ready for DeliveryNov 25,2025Crafted with attention to both form and function, the FX Series features a sleek, durable build that withstands tough working conditions while maintaining a professional appearance.

- Building a Stronger Pipeline: Your Guide to Selecting HDPE Fittings for a Leak-Free SystemNov 24,2025At Welping, we support your projects with a comprehensive portfolio of HDPE pipes and fittings, designed for diverse applications from municipal water supply to industrial and gas pipelines.

- Why the FUSINGX FX200 Series Is a Smart Choice for HDPE Pipe WeldingNov 24,2025The FUSINGX FX200 Series is a high-end butt fusion machine engineered for stable and precise HDPE welding.

Blog group

Are you looking for a reliable HDPE pipe fittings manufacturer?

We can quickly provide customers with market analysis, technical support and customized services.You can choose the solution that best fits your business

For standard pipe fusion applications, our FX series butt fusion welding machines are available as ready-to-use models with proven configurations and stable performance.

For customers who require branding adjustments or minor configuration changes, we offer OEM services based on existing FX platforms.

For more specific market or technical requirements, our ODM service supports the development of customized welding equipment—from structural design and functional configuration to testing and production.

This flexible cooperation model allows both new and established brands to enter or expand their markets efficiently, with different levels of customization as needed.

- Phone

- *Title

- *Content