Step 1

Requirement Collection

Customers provide design requirements, drawings, or samples.

Customers provide design requirements, drawings, or samples.

For the particular design and functionality, we will use the 3D drawings and send them to customers for confirmation.

After the customer confirms the drawings, we can provide an accurate quotation.

After price confirmation, we will arrange the production of tools and molds. Customers need to pay for the tooling and mold costs upfront, which will be refunded after bulk ordering.

After the tooling and molds are finalized, we will complete the production of the first sample within 30 days and send it to the customer for inspection.

Upon receiving the sample, customers will inspect and verify the first sample, and provide feedback on the inspection results to us.

Once the customer confirms the sample is qualified, we will begin mass production.

After production is completed, we will inspect the products for hardness, dimensions, run out, etc., to ensure 100% product compliance.

When the inspection results are OK and the customer confirms the shipment can proceed, we will arrange the booking and shipping.

High-precision cutting ensures precise and smooth edges.

Durable, stable welds for high structural strength.

Customized insulation and housing components.

Machining precision parts with micron-level accuracy.

Efficient aluminum part production with excellent dimensional stability.

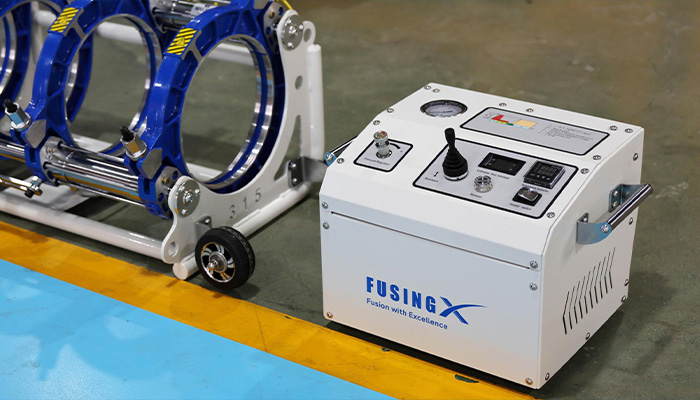

FusingX is born from Welping Machinery, a leader in welding equipment. Since 2021, Welping's products have been sold globally across South America, the Middle East, and Northern Europe, proven under demanding conditions. Four years of advanced production expertise, cutting-edge technology, and practical insights are fully integrated into FusingX. This means you receive not just a machine, but a mature system backed by a skilled technical team, robust production capacity, and efficient problem-solving capabilities—far surpassing ordinary domestic brands.

We never stop improving. Over the past year, our technical team has refined hundreds of details: using higher-quality components for extended longevity, employing high-strength materials to ensure structural rigidity, and implementing stricter quality control processes to eliminate defects. All aimed at one goal: delivering equipment with superior reliability, lasting performance, and outstanding productivity.

Time is money. As a direct manufacturer, we offer unparalleled supply chain advantages. When you need to replace wear-prone parts or any components, we respond immediately with genuine parts, drastically reducing downtime and keeping your projects moving forward smoothly—with zero hassle.

View Related Products