Butt Fusion Welding Machine - FX

Precise, intelligent, and durable, FusingX provides next-generation welding solutions for global piping professionals.

Hot Fusion Equipment

Intelligent control system:

Visual interface + automatic parameter control, lowering the operating threshold.

Data recording and traceability:

Built-in welding record system, supports report export, meets project filing requirements.

Modular design:

Easy to maintain and replace, extending equipment service life.

Lightweight and portable:

Convenient for field engineering work and mobile construction.

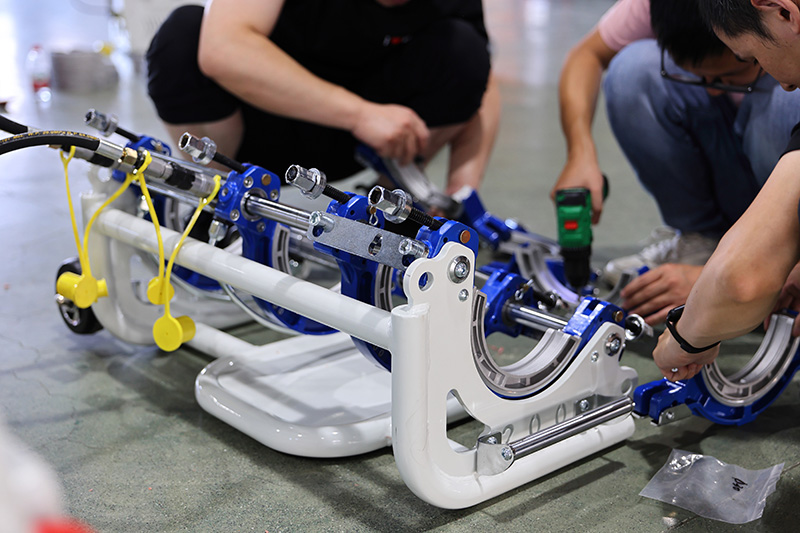

How Do We Deliver an Excellent Butt Fusion Machine?

Heating Plate Temperature Uniformity Test

Purpose: Ensure even temperature distribution across the heating plate surface

Ensured Performance: Uniform melting at the joint interface, preventing weak or overheated welds

Hydraulic System Pressure Accuracy Test

Purpose: Calibrate the output pressure precision of the hydraulic system

Ensured Performance: Consistent welding pressure for reliable joint quality

Alignment and Parallelism Verification

Purpose: Verify clamping alignment accuracy during pipe fitting

Ensured Performance: Perfectly aligned joints without offset or mismatch

Melt Pressure Maintenance Test

Purpose: Confirm stable pressure control during the melting phase

Ensured Performance: Proper molecular interdiffusion and dense joint structure

Cooling Time and Pressure Control Test

Purpose: Ensure maintained pressure and sufficient cooling duration

Ensured Performance: Strong, crack-free joint formation

Weld Cycle Data Traceability Test

Purpose: Record key welding parameters (temperature, pressure, time) for each joint

Ensured Performance: Full traceability and compliance with welding standards

Weld Joint Tensile and Peel Test

Purpose: Evaluate the mechanical strength of the welded joint

Ensured Performance: Evaluate the mechanical strength of the welded joint

Machine Endurance and Fatigue Test

Purpose: Simulate continuous high-frequency operation under real-world conditions

Ensured Performance: Long service life and reliability in demanding working environments

Why Choose FusingX ?

FusingX redefines pipe connections with precision, reliability and intelligent engineering.

FusingX: Designed for professionals, delivering exceptional performance.

※ High-precision manufacturing –

- Strict tolerances ensure perfect fit and long-term sealing performance

※ Intelligent welding technology –

- Automatic control, data logging, and intuitive operation ensure consistent welding results

※ Global certification standards –

- Products comply with ISO, EN, and ASTM standards, ensuring global compatibility

※ Comprehensive solutions –

- From fittings to machines to tools, providing seamless integration for every project

※ Global trust –

- Performance proven, recognised in over 50 countries and regions, with localised support and expert services

Industry Applications

Municipal Water Supply & Drainage Engineering

Gas Pipeline System Installation

Industrial Fluid Transport Retrofit

Farmland Irrigation Pipeline Laying

OEM Pipe Fitting Installation Cooperation Project

Partner with FusingX

—— Your Global HDPE Pipe Connection Solution Expert

Choosing FusingX, Choosing Excellence!

For standard pipe fusion applications, our FX series butt fusion welding machines are available as ready-to-use models with proven configurations and stable performance.

For customers who require branding adjustments or minor configuration changes, we offer OEM services based on existing FX platforms.

For more specific market or technical requirements, our ODM service supports the development of customized welding equipment—from structural design and functional configuration to testing and production.

This flexible cooperation model allows both new and established brands to enter or expand their markets efficiently, with different levels of customization as needed.

- Phone

- *Title

- *Content