Home / All / Pipe Fittings / Electrofusion Fittings / FusingX 90° Elbow Electrofusion Fittings For Reliable Pipe Fittings

FusingX 90° Elbow Electrofusion Fittings For Reliable Pipe Fittings

Detail Information

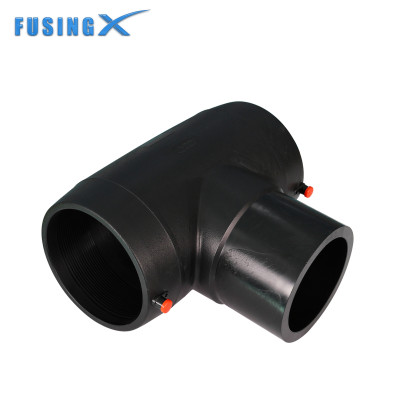

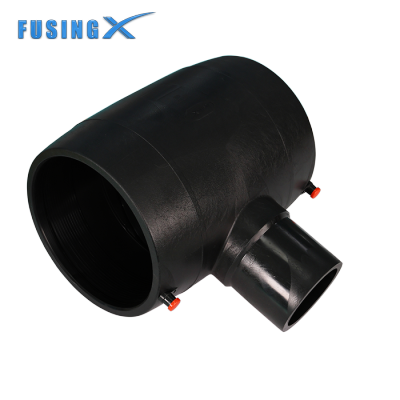

90° Elbow — Electrofusion Fitting

FusingX Electrofusion 90° Elbow

Product Overview

ELectrofusion Fitting 90° Elbow

· Material: PE100

· Pressure rating: PN16

· Size range: DN63–DN315

· Connection: Electrofusion

· Application: PE pipeline systems

Electrofusion Structure & Details

· Electrofusion terminals: Connect to standard electrofusion control units

· Heating coil area: Embedded coil inside the socket for electrofusion welding

Detail views of the body, socket surface, and terminal area

Selection Notes

· Select size according to pipe outside diameter (DN).

· Confirm required pressure class (e.g. PN16).

· Verify applicable project standards and welding parameters with the electrofusion control unit.

FX Series – System View

FusingX FX Series – System View

FX series focuses on professional pipeline fusion systems.

· Electrofusion fittings

· Electrofusion control units

· Butt fusion machines

Related Products

Review

- Loading...

You can choose the solution that best fits your business

For standard pipe fusion applications, our FX series butt fusion welding machines are available as ready-to-use models with proven configurations and stable performance.

For customers who require branding adjustments or minor configuration changes, we offer OEM services based on existing FX platforms.

For more specific market or technical requirements, our ODM service supports the development of customized welding equipment—from structural design and functional configuration to testing and production.

This flexible cooperation model allows both new and established brands to enter or expand their markets efficiently, with different levels of customization as needed.

- Mobile Phone

- *Title

- *Content

You can choose the solution that best fits your business

For standard pipe fusion applications, our FX series butt fusion welding machines are available as ready-to-use models with proven configurations and stable performance.

For customers who require branding adjustments or minor configuration changes, we offer OEM services based on existing FX platforms.

For more specific market or technical requirements, our ODM service supports the development of customized welding equipment—from structural design and functional configuration to testing and production.

This flexible cooperation model allows both new and established brands to enter or expand their markets efficiently, with different levels of customization as needed.

- Mobile Phone

- *Title

- *Content